The project entails the implementation of a sustainable hydrogen generation unit based on photovoltaic electricity generated in the roof of a mill.

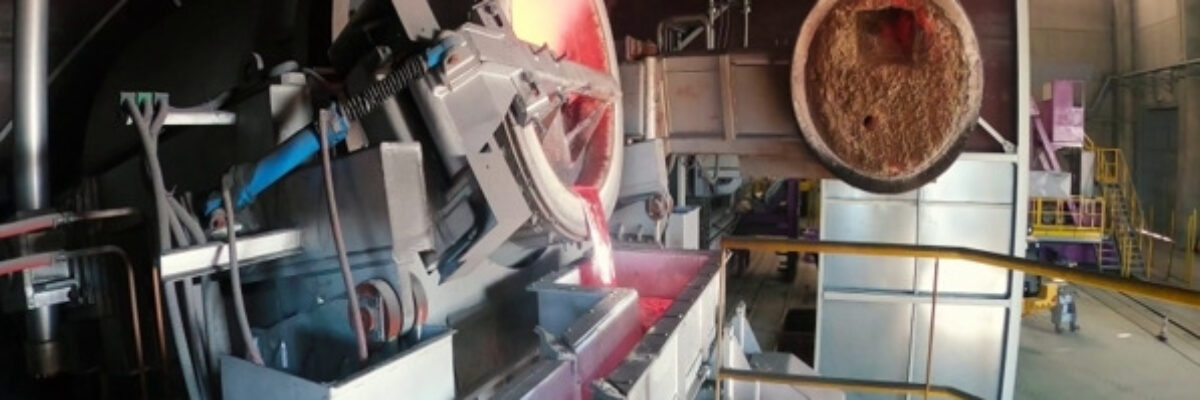

The hydrogen generated will initially be stored at a pressure of 16 bar for production purposes, and subsequently mixed in a ratio of 20% with natural gas to provide fuel for the secondary aluminium melting furnaces.

It has been designed with an electrolyser H2B2 model EL200.

TRESCA Ingenieria was tasked with the design of the facility, which comprises:

- Generation by Photovoltaic on roof

- Power of the Renewable Installation 1.5 MW

- Electrolyser Power 1055 Kw

- Type of Electrolyser PEM (Proton Exchange membrane, caustic free)

- Amount of H2 generated 103 Nm3/h (220 kg/day)

- Destination for blending with natural gas and feeding aluminium melting furnaces

WORKS:

Civil

Electric

Mechanical